Wire Rope

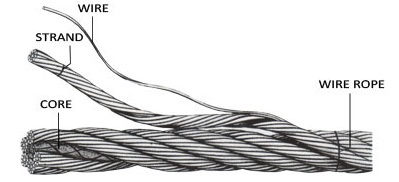

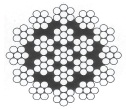

Wire rope is generally composed of wires, strands and core.

Wire rope varies:

• By Diameter

• The Grade of Steel

Wire rope may be manufactured from many grades and types of steel and alloys. Some of the more common grades are as follows:

IPS (1770 Grade) – Improved Plow Steel

EIPS (1960 Grade) – Extra Improved Plow Steel

EEIPS (2160 Grade) – Extra Extra Improved Plow Steel

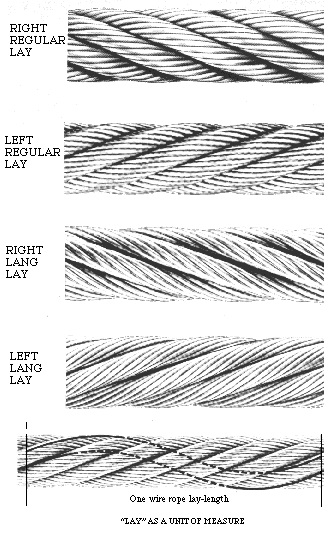

• Rope Lay

The “Lay” of the wire rope directly affects the operating properties.

The two most common types are:

1. Ordinary (or Regular) Lay

In Ordinary Lay wire rope, the direction of the wires is twisted in an opposite direction than the direction of the strands. Ordinary Lay may be Right Ordinary Lay or Left Ordinary Lay

Therefore,

Right Hand Ordinary Lay (or Right Hand Regular Lay) = RHOL (or RHRL) = Z Lay

Left Hand Ordinary Lay (or Left Hand Regular Lay) = LHOL (or LHRL) = S Lay

2. Lang Lay

In Lang Lay wire rope the direction of the wires are twisted in the same direction as the strands. Lang Lay may be Right Lang Lay or Left Lang Lay depending upon the direction of the strands.

The wires of an ordinary lay wire rope seem to travel parallel and along the length of the rope while those of a lang lay rope appear to travel around the rope.

• The Finish on The Wire

Most wire rope has an ungalvanised or galvanised finish. In addition, many wire ropes are stainless steel, or plastic/vinyl/urethane coated.

• The Core Material

The core is the central member about which the main strands are laid. Its main purpose is to provide support to the outer strands. Most wire ropes are supplied with either a fiber or steel core.

Fiber Cores – Natural Fiber Core or Synthetic Fiber Core (FC)

Steel cores – Independent Wire Rope Core (IWRC) or Wire Strand Core (WSC)

These steel cores provide more support than fiber cores to the outer strands. Steel cores resist crushing, are more resistant to heat, reduce the amount of stretch, and increase the strength of the rope.

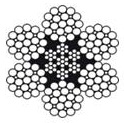

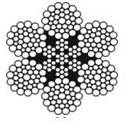

• Wire Rope Construction

There are hundreds of wire rope constructions; some of the more common arrangements are as follows: